RON HAZELTON: Our first house call today is in West Dennis, Massachusetts where Len and Suzanne MediaVilla needs some help to build back stairs for their front porch.

LEN MEDIAVILLA: Hi, Ron. We’re just getting ready for you.

RON HAZELTON: Hey guys! How are you?

LEN MEDIAVILLA: Good.

RON HAZELTON: Suzanne? Len?

SUZANNE MEDIAVILLA: Hi Ron.

RON HAZELTON: Oh, man I can smell the ocean from here. We must be very close, huh?

LEN MEDIAVILLA: It’s here. It’s here.

RON HAZELTON: Can we see it from up here?

LEN MEDIAVILLA: Yup.

RON HAZELTON: Okay, I want to go up there and get a view later on.

LEN MEDIAVILLA: Okay.

RON HAZELTON: Show me the project, would you?

LEN MEDIAVILLA: Sure. Come on back.

RON HAZELTON: You built this house yourself?

LEN MEDIAVILLA: Yes we did.

RON HAZELTON: Ah, this is it, huh?

LEN MEDIAVILLA: Yeah.

RON HAZELTON: So the stairs are going to what? Go right down here?

LEN MEDIAVILLA: Yup, right down here.

RON HAZELTON: To the landing?

LEN MEDIAVILLA: To the landing. And we’re going to put a 4x4 post here.

SUZANNE MEDIAVILLA: And one here.

LEN MEDIAVILLA: And then we want to tie that into this area here with this post.

RON HAZELTON: So this all goes? The railing comes out?

LEN MEDIAVILLA: Yup. All four of those.

RON HAZELTON: Now instead of pouring concrete down here you’ve decided to put these pavers in, right?

LEN MEDIAVILLA: Yes. Right.

RON HAZELTON: On the sand?

LEN MEDIAVILLA: Right on the sand.

RON HAZELTON: Which you’ve got plenty of here on the Cape, right?

LEN MEDIAVILLA: It’s all sand, yup.

RON HAZELTON: Okay. Well, let’s grab some materials guys and get to work.

LEN AND SUZANNE MEDIAVILLA: Okay.

RON HAZELTON: Okay Lenny, drop that back in there would you?

LEN MEDIAVILLA: Sure will.

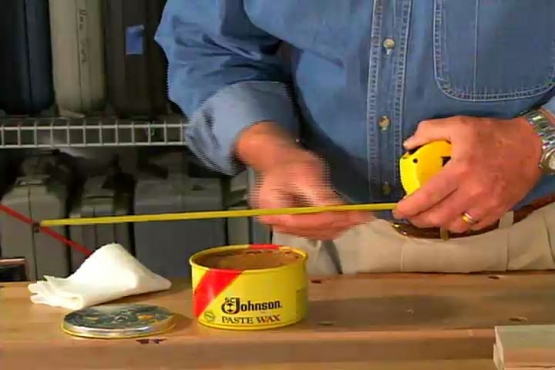

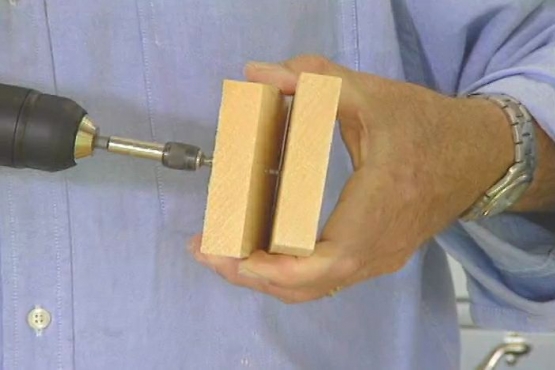

RON HAZELTON: And Suzanne if you would put the string around here. Now this is what is going to actually support the stairs. It’s the bones of the stairs, if you will. Len bought pre-cut stringers for this job. And while the pre-cuts make the job easier, they do require that the landing at the bottom of the stairs be at just the right height. In this case, we have to raise the landing, which is made of concrete pavers, by adding sand underneath. Len, what we need to do, in effect, is to make an extension to your rim joist there; kind of a ledger. You see this is the position for the stringer, it’s actually hang down below this rim joist. So, in effect, we have to make the rim joist wider. We’ll widen the rim joist by attaching a piece of 2x4 to a piece of 2x10. Then, we attach this assembly to the rim joist with rust resistant screws. Now, I’ve marked the location of the stringers. Actually we are going to use four of them in this stairway. One here, here, here, and here. The reason I have done that now is I am going to be attaching this to the rim joist with carriage bolts and I don’t want those carriage bolts to be in the way of the stringers. Now it’s time to attach the first stringer. I have temporarily attached a joist hanger to the top of the stringer, which will hold it in place while we drill holes for lag screws. With everything properly positioned, I drill clearance holes through the rim joist, and pilot holes in the end of the stringer. Okay we’re going to take this off now. Now we are going to remove the temporary joist hanger. Now I am going to drill what I call a clearance hole. I want this to be able to slip right through this board here.

SUZANNE MEDIAVILLA: hm-hm.

RON HAZELTON: And only bite into the stringer, so we use a larger drill. There you go. I am going to hold this up here and you put it through. Next, we attach hex-head screws. This will make the permanent attachment. This is going to a sense of accomplishment and satisfaction. You got it Suzanne? Last one?

SUZANNE MEDIAVILLA: Yeah, I think so.

RON HAZELTON: Great. With all four stringers attached it is time to install the risers. To avoid rust and corrosion we’ll use stainless steel screws. Okay, Suzanne, why don’ t you try some. Have you done this before?

SUZANNE MEDIAVILLA: Not with this type of drill.

RON HAZELTON: Okay this is a special square head driver. Stainless steel screws. These don’t strip out at easily as the phillips, so give it a try. Okay. Good work. There, excellent. Looking good, okay now it is time for the treads. This is a stair tread, guys. This is one you walk on of course. I want to make sure that the overhang is the same on both sides. It’s a 2x12 pressure treated, it should be about a half inch, Len.

LEN MEDIAVILLA: Okay, it’s a half inch.

RON HAZELTON: Okay, Suzanne if you would check over there. When you guys tell me its straight…

SUZANNE MEDIAVILLA: Half inch here.

RON HAZELTON: Okay, I’ll draw a small line here. That’s right down the center of the stringer and then we’ll attach it with more of these stainless steel screws. Good, now we’ll do this for each one of these stringers. Folks, it’s time to cut away the old rail. So, Len, no…let’s let Suzanne do this. This is our reciprocating saw, okay? Although Suzanne had never used a power saw before, it didn’t take her long to get the hang of it. In the short time that it took to remove the railing, she had become pretty comfortable with this power tool.

SUZANNE MEDIAVILLA: Wow! I actually did it.

RON HAZELTON: You did do it. This machine is mean, but not too mean for you. Before we put on this final tread we are going to install this post which is will be the bottom post for this handrail. So Len, if you could hold that right there. This is a 4x4. There you go. Here’s a clamp, you can just clamp that in place. Once the post is plum, or vertical, we drill the holes for carriage bolts. Then Suzanne snugs them up with a socket wrench. Meanwhile, I’ll trim the ends of the existing rail, which we cut, using my Japanese hand saw. And then round the ends using a jig saw. Before we can install the final tread, we need to notch the ends so that it can fit around the post. Now this is going to be one part of the handrail guys. So it is important to right now to sort of figure out what our angles are going to be. Suzanne hold that right there for me, right there at the front edge of that post, would you? And I’ve measured up the same distance on this one as from here to here. Okay, got that? Okay, so let me draw this angle in right here. This bevel gauge will allow me to transfer the angle that I just drew on the railing to the power-miter box. Swing the bed to the edge of this cut groove right here. It lines right up with that bevel gauge. With the angles set, the cuts are made. Now the angles should be an exact match.

SUZANNE MEDIAVILLA: Perfect.

RON HAZELTON: Before we attach the railing I make an angled cut at the top of the post. Then, we screw the top rail in place. Good. Okay. Let’s take the clamp off. Len why don’ t you put the other two screws and I’ll start cutting the top of the hand rail. Well, as the sun is going down we are putting in the last few pieces. This is the top of the handrail right here. We want this to overhang about 3/8 of an inch. Let’s get our combination square after that. There we go, okay. Now Suzanne could you hold that right there. Once the handrail is centered and clamped into place, Suzanne attaches it to the top of the railing using those stainless steel screws. Very nice. Well I was going to head down the road this morning, but, you know, for me, some of these projects just take longer than you think. So I am going to head over to wake up Len and Suzanne in a moment and we’re going to finish up those steps, right after I have some breakfast. Hey Lenny, Suzanne, good morning!

LEN AND SUZANNE MEDIAVILLA: Good morning Ron!

RON HAZELTON: Ready to go to work?

LEN MEDIAVILLA: Sure are!

RON HAZELTON: Come on down. Hey good morning guys. Gee, what a gorgeous morning this. Alright, let’s just pick this up where we left off on the handrails or the lower section of the handrails. Before it got too dark yesterday we had cut and measured the lower railing, so all we have to do this morning is attach it. There we go. Okay then, Len, if you would do the other two down at the bottom there, sir?

LEN MEDIAVILLA: Will do.

RON HAZELTON: And I’ll grab the other rails. Well look at what you two have done. Huh? Can you imagine this? Now yesterday there was nothing here and now there are steps. Fantastic job, guys. I had a good time.

LEN AND SUZANNE MEDIAVILLA: So did we Ron! Thanks, Ron. A lot of fun!