Polystyrene Crown Molding Looks Great and Goes Up Without Nails

Lightweight, Foam Molding Can Be Put Up by One Person in a Couple of Hours

This post is in partnership with Creative Crown. The opinions are my own.

Click here to learn more about the Creative Crown molding featured in this video.

If you love crown molding but have been put off by the thought of hammers, nails, compressors, hoses and nailing guns, then polystyrene crown trim could be just what you’ve been looking for.

Sent Right to My Door

Sent Right to My Door

No trip to the home improvement center or lumber yard is necessary. The molding I used for this project arrived in a single carton. The sections were eight feet long and, quite literally, light as a feather.

Cuts Cleanly with a

Cuts Cleanly with a

Miter Saw

A standard miter saw slices through this material in a flash. The molding can be cut in the vertical position with a 45-degree miter setting or in the horizontal position using a bevel cut.

Look, No Nails

Look, No Nails

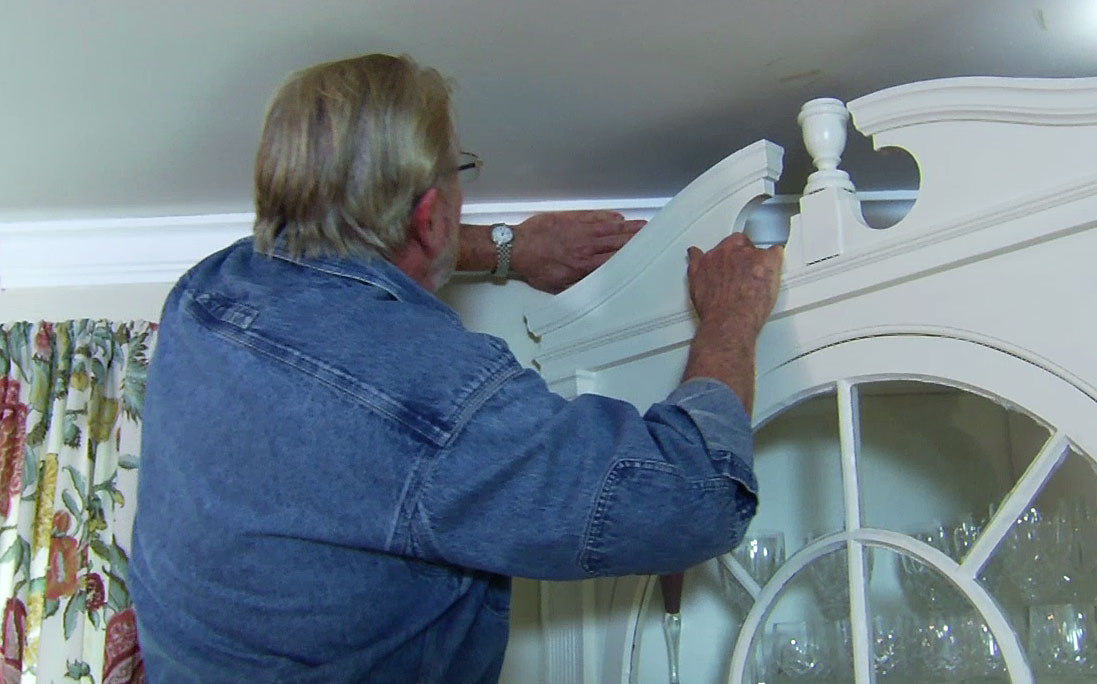

No fasteners of any kind are needed. Instead, the molding is secured in place with simple painters' caulk that’s applied in beads to the back of the material. Hand pressure is all that’s needed to bond the trim to the wall. This is especially helpful when having to install the crown behind built-in cabinets that cannot be moved.

Working Alone?

No Problem. Because the sections are a manageable eight feet in length and so lightweight, it’s simple to work solo. An entire room can be completed in just a couple of hours. Creative Crown also makes molding that works equally well on cathedral or vaulted ceilings.

Smooth Finish. Crisp Profiles.

Smooth Finish. Crisp Profiles.

This new generation of polystyrene is glass smooth. Right out of the box it can be painted with one coat. Painting can be done after installation by masking the walls and ceiling, but I found it simpler to paint beforehand. The traditional crown details are sharp and clean.

Recommended Articles

The How’s and Why’s of Upgrading a Central AC System

A step-by-step video demonstration showing removal and replacement of a central air conditioning system. Includes advantages of new, state-of the-art AC systems.

If You’ve Got a Project That Involves Demolition, You’ll Want to Know About This Tool.

I try out a new tool designed and engineered to do one task exceptionally well -- demolition.