How to Make a Spice Rack

How to build and install a wall-mounted spice rack; includes step-by-step instructions along with tips.

This custom made rack is designed to keep dried herbs, spices and other seasonings visible, organized and well within arm’s reach. The techniques used to build it are the same as those you’d employ to fashion just about any kind of small cabinet. So, even if you’re not really a foodie, you can use the same basic approach to build a small display cabinet, a craft supply organizer or whatever.

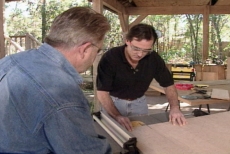

Cut Cabinet, Shelves and Dividers for the Spice Rack

Use 4 x 8 sheets of 3/4-inch thick oak-veneer plywood and rip the spice rack/cabinet components on a table saw. You will need top, bottom, sides, back, shelves, and dividers.

Cross Cut the Spice Rack Components to Length

Use a table saw with a cradle to cross cut each component to proper length. Align the cut marks with the kerf/blade slot cut in the cradle bottom. Clamp a notched stop to the rear edge of the cradle.

Cut Rabbets with Dado Blades to Make Stronger Cabinet Joints

Cut rabbets with the table saw and data blades to facilitate spice rack assembly and make stronger cabinet joints. Install a narrow series of dado blades with chippers to cut rabbets down the back edge of each side panel.

Adjust for Wider Rabbets on Spire Rack Top and Bottom

Expose more dado blade to cut wider rabbets by adjusting the table saw/fence further back from the blade. Wider rabbets are required where the top and bottom panels will fit into the sides of the spice rack.

Cut Dados for the Spice Rack Fixed Shelf and Dividers

Leave the dado set installed on the table saw. Use the cradle again to position components for cutting dados in the sides for the fixed shelf and in the fixed shelf and the bottom for the spice rack dividers

Drill Rows of Peg Holes in the Sides and Dividers

Use a portable drill press to bore two equally-spaced rows of peg holes in the sides and dividers that will hold the adjustable shelves. Clamp temporary pegboard along the length of the spice rack component for a drilling template.

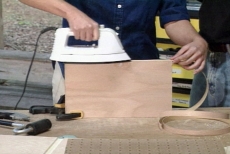

Face Raw Edges of Spice Rack Shelves with Wooden Edge-banding

Cover the front edges of the spice rack shelves with wooden edge-banding to make the plywood look like solid wood. Melt the heat-activated backing onto the plywood with a common household iron and press firmly with a laminate roller.

Dry Fit and Then Permanently Assemble the Spice Rack

Brush rabbets with glue and permanently assemble spice rack components after a dry fitting. Clamp the spice rack joints until the glue sets. Secure them with nails. Slide the dividers into place and secure them with finish nails.

Cover Spice Rack Cabinet Edges with Face Framing

Apply glue to the unfinished front edge of the cabinet and position 1 1/2 inch strips of molding as face framing to give the spice rack and more-finished and substantial look. Secure the glued strips with finishing nails.

Apply Stain to the Spice Rack with Paint Pads

Stain the spice rack to match the existing kitchen cabinets. Apply the stain with paint pads to minimize drips and runs. Mount the cabinet to the wall stud. Insert shelf brackets/pegs into the holes as desired and add adjustable shelves.

Related Tips

Blog Articles

Maximize Your Yield with DIY Netting for Strawberry Beds

Keep your strawberries safe from pests with our DIY strawberry cage netting solution. Learn how to create sturdy frames and find the best netting for your strawberry plants.

Change It Up: Swapping Out Your Light Switch Plates

Tired of boring light switch covers? Upgrade your home decor with this simple guide on replacing light switch plates and make a statement in every room.

Revamp Your Outdoor Space: How To Stencil A Concrete Patio

Learn how to create a stunning patterned concrete patio with our easy-to-follow instructions for stenciling. Upgrade your outdoor space in no time.