Patch Wooden Flooring – Learn How to Do It Yourself

Repair a Hole in an Oak Tongue and Groove Floor and Finish the Patch to Match in Color and Gloss

Patch small holes and imperfections in oak tongue and groove hardwood flooring and its finish to invisibly repair damage or unsightly areas. Whether the blemishes are from wear and tear or through-and-through holes revealed through remodeling, replacement tongue and groove planks can be cut, shaped and installed in staggered design to match the irregular pattern and tone of original flooring.

Read More

Split Planks for Removal by Plunge-cutting with a Circular Saw

Split only the damaged planks in the hardwood floor restoration area to facilitate their removal. Set the circular saw blade just deep enough relative to the saw's baseplate to cut through 3/4-inch flooring and make plunge cuts.

Score and Chisel-cut the Ends and Pry Out Split Planks

Score each end of the damaged planks with a utility knife and straight-edge. Make straight and angled cuts with a hammer and chisel along the scores to loosen the planks. Pry out split planks without stressing the adjacent boards.

Sand Damaged Flooring with 60-Grit Sandpaper and a Belt Sander

Resurface the rough and unsightly hardwood floor repair area only. Avoid scuffing adjacent undamaged areas. Use a fairly coarse sandpaper, 60-grit for this hardwood floor restoration, on a small belt sander and work in the direction of the wood's grain.

Remove Part of Groove so that Planks Drop into Position

Cut replacement planks for the patch to length. Adjusting table saw blade to remove the bottom portion of each plank's grooved side to allow it to drop in rather than fitting on the tongue. Tap with a mallet to seat.

Face-nail with a Pneumatic Nail Gun to Secure Replacement Planks

Secure the new planks by face-nailing them with a pneumatic nail gun. Edge-nailing through the tongue is impossible because the planks were adjusted and dropped into place rather than fitting them with their original tongue and groove design.

Sand within Edges of Target Planks Prior to Refinishing

Sand/scrape planks with the grain. Confine resurfacing efforts to individual planks, shortening their apparent length by scoring false joints to avoid reworking an entire board. Blend the repair into the natural variation of the floor's color and grain.

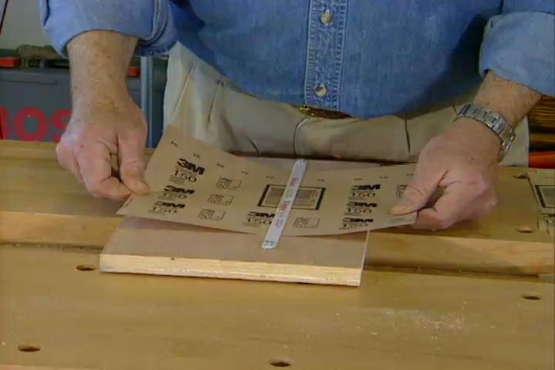

Fill Nail Holes and Sand Again with Fine Paper

Fill nail holes with wood putty stained to match. Perform a final sanding with a block and fine sandpaper, staying within the borders of the target planks. Remove dust with a tack cloth.

Consider the Logistics of Matching the Original Finish

Determine how to apply a finish that matches the original in color and sheen. Clear polyurethane yellows and darkens with age, so we have diluted shellac in alcohol and brushed on a light toning coat to approximate the aged color.

Apply a Top Coat of Polyurethane to Seal the Repair

Top-coat the repair with clear polyurethane to seal the planks and add gloss and durability. A cheap foam applicator works well on the narrow individual planks to avoid coating adjacent boards. Discard the foam applicator when the project is complete.

Related Tips

Blog Articles

Creating a Glossy Bar Top Finish: A DIY Guide

Have you ever wanted to elevate the look of your home bar that looks like liquid glass? A glossy bar top can add a touch of sophistication and style to your space. In this DIY guide, we will walk you through the steps to create a stunning glossy bar top that will impress your guests and elevate your home entertainment experience.

Techniques for using Heavy-Weight and Light-Weight Spackle

A ding, small hole, or big scratch is bound to be in almost any home. Whether caused by moving heavy furniture or daily wear and tear, it’s something that is easily repaired. Did you know that there are two types of patching compounds used for repairing holes, dents, and cracks in walls?

Shiplap: The Wood That Says “Welcome Home”

Imagine a cozy cabin nestled in a snowy forest. What's one of the first things you notice? The warm, inviting shiplap walls, of course. Shiplap is synonymous with comfort, wrapping you in its rustic charm and timeless appeal. It's the wood that says, "Come on in, you belong here."