How to Build a Custom Workbench

Construct a Modular Wooden Workbench with Three Base Units That Join to Form a Forth Dropped Surface for Your Saw

Build a custom L-shaped workbench of three separate tool benches that join to form a fourth work surface--a dropped well for your miter saw. Construct the base units of two-by four components surfaced with medium-density fiberboard (MDF) that can be replaced easily when scarred and dented beyond use. Use screws, glue, and double-faced tape to secure and join components.

Read More

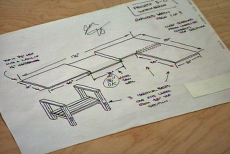

Diagram Your Project and Make a Cut List

Plan your workshop workbench carefully and diagram the dimensions. Make a cut list of pieces to cut, especially when several are the same size. Set up saw horses and lumber as a temporary woodworking bench for cutting components.

Cut All Components, Measuring against a Stop Block

Transfer the bench leg length onto a two-by-four and clamp a stop block at the mark. Butt each two-by-four against the stop block as you cut to ensure consistent length. Repeat the process for each component of a different dimension.

Cut Mortises in Bench Leg Components for Cross Rails

Mark and then position a pair of bench legs for repeated cuts with a sliding compound miter. Cut half-way through each two-by-four to notch out matching mortises across each pair. When joined, the two-by-fours will become four-by-fours with a mortise.

Assemble End Frames from Bench Legs and Cross Rails/Braces

Apply glue to the interior surface of each pair of leg components and their mortises. Sandwich a cross rail between the two and secure with screws. Glue and screw another brace across the top of the end frame.

Join Two End Frames with Side Rails for Each Base

Position and clamp together two end frames with two side rails for each workbench base. Attach them at the upper end and secure the rails with screws.

Secure Bottom Braces Side-by-side across the Bottom Rail

Lay multiple bottom braces/planks side-by-side to span the space between the cross rails. Secure each with screws driven through them and into the cross rails beneath to provide structural reinforcement and a handy shelf.

Cut Workbench Tops from Sheets of Medium-Density Fiberboard

Measure and mark cut lines for workbench tops on sheets of 3/4-inch MDF. Use a clamping straight edge and a circular saw to ensure straight cuts every time. Attach tops to the bases with countersunk screws to avoid scratching projects.

Position Three Workbench Bases in an L-Shape with a Gap

Set bases in an L-shaped configuration, leaving a gap for the well. Span the gap for the well with two-by-four rails and slide in the top. Secure replaceable MDF panels on top of each bench top with double-faced tape.

Related Tips

Blog Articles

Expert Tips: How to Mount a TV on the Wall

Get step-by-step instructions on how to mount a TV on the wall, especially for big screen TVs. Master the art of wall mounting with our tips.

Frustrated by Stripped Screws? Here’s How to Get Them Out Fast

We've all been there. You're in the middle of a project, and suddenly your screwdriver spins uselessly in the screw head. The screw is stripped, and frustration sets in. With a little know-how and this simple trick, you can tackle a stripped screw and get your project back on track.

The Secret to Finishing Plywood Edges

Plywood projects are fantastic, but exposed edges can be an eyesore. This blog post unveils the magic of edge banding - a simple technique to create flawless, finished edges on your plywood projects, making them look professional and ready for paint or stain. Watch the video to learn how to apply edge banding like a pro!