RON HAZELTON:

Well, I'm headed down to Cape Coral, Florida. Now Steve and Barb Hirsch have a very nice house down there. They want to put some ceiling panels in their family room. I'm going to see if I can help out.

Their roomy, Spanish-style home is typical of those built here in recent years but their idea for dressing it up, isn't. They've invited me to Cape Coral to help them give their dim ceiling a dramatic new look.

BARB HIRSCH:

We'd been to a restaurant in Ft. Myers that had a ceiling done in pecky cypress. And as a matter of fact, I'm sure they thought we were rather strange because instead of sitting there eating, he was standing up taking pictures of the ceiling with his camera.

RON HAZELTON:

[LAUGHS] Anybody come over and say, what the heck are you doing?

BARB HIRSCH:

Well, I was waiting for them to do that.

RON HAZELTON:

So this was the restaurant here.

Now wood ceiling panels are usually made from pine but the Hirschs fell in love with this once-abundant-but-now-rare native Florida wood called pecky cypress and special-ordered it from their home improvement center.

Pecky refers to the pockmarks or elongated holes that give this wood its unique character.

STEVE HIRSCH:

But apparently when the bark gets damaged or a branch breaks off, fungus actually invades the tree and then works its way up in the little rings here where the, where the moisture would go —

RON HAZELTON:

After removing all the furniture, Steve and Barb use electronic stud finders to locate all the ceiling joists. They identify the location of each joist by snapping chalk lines. Our paneling planks will run perpendicular to the joists and will be nailed into them.

But first the planks need to be cut to fit inside the beams. So Steve takes a measurement.

STEVE HIRSCH:

I’m saying this looks like 61-and-1/4 here.

BARB HIRSCH:

Okay.

RON HAZELTON:

Now it's likely there could be as much as a 1/4-inch difference between the beams from one end of each section to the other. So measurements are made about every 12 inches.

STEVE HIRSCH:

Like 61-and-3/8ths.

RON HAZELTON:

Hey guys.

STEVE HIRSCH:

Hi.

BARB HIRSCH:

Hi.

RON HAZELTON:

All finished?

BARB HIRSCH:

Oh, yes, have all the measurements.

STEVE HIRSCH:

Yep, they're all done.

RON HAZELTON:

All the measurements, all the studs are marked, we're ready to cut.

[BOTH SPEAK AT ONCE]

BARB HIRSCH:

That's right. We're ready to cut.

RON HAZELTON:

And so what, what do we want to cut first, what length?

STEVE HIRSCH:

Well, I guess we came up the — the first section is off just a hair so probably about half of them go in at 61-and-an-1/8th and the rest of them at 61-and-1/4 inches.

RON HAZELTON:

Okay. So here's the way this thing works over here.

BARB HIRSCH:

Okay.

RON HAZELTON:

— is we just loosen this up and we're going to do the 61-and-1/8th first, so we've set the edge of this right there at 61-and-1/8th. That way we don't have to measure each board. I've precut the end here, so we got a nice square end to start with.

STEVE HIRSCH:

Okay.

RON HAZELTON:

So who wants to cut first? I think it should be Barb.

BARB HIRSCH:

Oh you’re giving it to me. Okay.

RON HAZELTON:

Okay. Bring it out like this.

BARB HIRSCH:

Okay.

RON HAZELTON:

Bring it all the way down till it stops and then push it all the way in till it stops.

BARB HIRSCH:

Okay.

RON HAZELTON:

Let it come up and then release the trigger.

BARB HIRSCH:

Okay.

STEVE HIRSCH:

Our measurement is one inch off.

RON HAZELTON:

Oh, really?

STEVE HIRSCH:

Where it's, where it's 60-and-1/8th versus 61-and-1/8th.

RON HAZELTON:

Moi did that?

[LAUGHTER]

RON HAZELTON:

Oh.

BARB HIRSCH:

It must have slipped.

RON HAZELTON:

This is, this is why my things never fit, I just realized now. Only — it's only an inch. Thank you very much for catching that. Now this is very embarrassing. I hope that we cut this out of the show.

[BARB LAUGHS]

RON HAZELTON:

Well, for the [LAUGHS] expert set straight by his student, Barb cuts the first of several planks at 61. I know, I know, 61-and-1/8th.

STEVE HIRSCH:

There you go.

BARB HIRSCH:

That's wonderful.

RON HAZELTON:

How was that, huh?

BARB HIRSCH:

That was great.

RON HAZELTON:

Steve cuts the next batch of board slightly longer, since the distance between the beams is wider at one end.

Now we've got one little problem here —there's a corner that's sort of cut off right here because of this fan light-box, so we're going to have to cut an angle on the end of this first board. First of all, I want to measure from this corner down to see where that angle starts. That's about 55-and-1/2. We'll mark that on the board.

And then I want to see what the actual angle is. This is called a bevel gauge. I'm going to put it right in here, one side on that wall, one side over here and that's the angle that we need to accomplish.

So this is the angle that we took off the ceiling.

BARB HIRSCH:

Okay.

RON HAZELTON:

What we're going to do is lay this bevel gauge right here on the saw and we're going to rotate the saw table right here, until the edge lines up with that bevel gauge. Then we'll take the board, so we'll slide that down. Now you want to put the left edge of the blade on that little mark right there. [SAWING SOUNDS]

Okay, Barb, hand that board up there. Let's see what kind of an angle cutter you are.

BARB HIRSCH:

Okay.

RON HAZELTON:

Drop it in here. Ho ho, I'd say that's just about perfection.

BARB HIRSCH:

Okay.

RON HAZELTON:

It's the best.

STEVE HIRSCH:

Great.

BARB HIRSCH:

Great.

RON HAZELTON:

Okay, guys. I think we can start to glue these up.

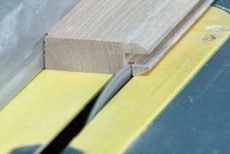

Well, we've cut enough paneling for this first section up here. Now this is called tongue-and-groove paneling. Why, because each piece has a tongue and a groove. A tongue on one side, a groove on the other side. When we put this up, we're going to slip that tongue into the groove and this gives us quite a bit of strength.

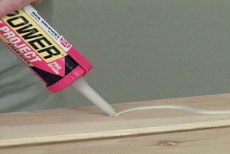

We're going to attach this up mostly with construction or panel adhesive. I'm going to put some on right now. I'm going to kind of apply this in sort of a serpentine pattern like this. Not too much, I don't want to make this too thick. Okay, guys, first board coming up, all right?

So this is the one with the angle cut on the end. Put it right up there in the corner like we did before. Push it in and then push it up to the ceiling. Now pull it down from the ceiling. Pull it down again and then put it back up. That will make sure that the adhesive gets distributed.

All right. Now you've got the pneumatic nail gun, you've got your ceiling joists marked, put a couple nails right into the joist there. [NAILING SOUNDS] We're off and running, guys. Here comes your next board.

BARB HIRSCH:

Okay.

RON HAZELTON:

Remember, the groove now is going to engage the tongue and then push it up and then pull it down just a little bit and then put it up again. [NAILING SOUNDS]

BARB HIRSCH:

Okay.

RON HAZELTON:

Okay, waiting on the glue man, huh?

BARB HIRSCH:

Right.

[MUSIC, NAILING SOUNDS]

RON HAZELTON:

When we reach the wall, we're left with a gap narrower than our planks. So we measure it, transfer that distance to a plank and rip it to size on the table saw.

Now Steve, here's the strip that you cut off. Before we put it up, we're going to have to make a little modification to it. And I've made up a little demo here to show you why. We want this to drop in next to that last full board, but you see, one side of the groove there is going to be getting in the way.

So what we're going to have to do is cut that one-half of the groove off so that this just drops in like that.

STEVE HIRSCH:

Okay.

RON HAZELTON:

Then we'll glue and nail it in place.

I've lowered the blade on the table saw and Steve pushes the plank through, taking off only the bottom lip of the groove. Now it's simple to slip the narrow board into the gap. Then we glue and nail it into place. Once it's up, we move on to the next ceiling section.

Well, the boards go up nice and easy until we reach this speaker hole which we must cut around. Barb and Steve hold the first panel that overlaps the hole in place. Steve traces the arc onto the back and then cuts it out with a jigsaw.

BARB HIRSCH:

Looks good.

STEVE HIRSCH:

Okay, great.

RON HAZELTON:

Steve applies the adhesive and Barb nails the board into place. Since the second panel would completely cover the hole, we first cut it into two pieces, leaving the end of the first piece slightly overlapping the hole. This time we trace the arc of the circle on the end of the plank. Then Barb takes a turn on the jigsaw to cut it to shape.

We repeat the process on the other side of the hole. Finally, Barb and Steve trace and cut the third board, exactly as they did the first.

STEVE HIRSCH:

We'll try and fit the speaker support rig —oh, look at that, just like downtown, couldn't be better.

RON HAZELTON:

With the speaker hole out of the way, we take a little break from the ceiling panels and move outside to paint some wood molding which we'll use to frame each ceiling section.

All right, now I may have cut this a little bit long because I'd rather be long than short. Let's see, ooh —

[BOTH SPEAK AT ONCE]

— oh, my gosh.

STEVE HIRSCH:

It seems to be just about perfect.

RON HAZELTON:

Boy, now that is sheer luck. It never happens. [LAUGHS]

BARB HIRSCH:

Looks pretty good.

RON HAZELTON:

Except when I'm working with you, Steve.

STEVE HIRSCH:

I know —

[BARB LAUGHS]

RON HAZELTON:

You're a good omen.

We work our way around each section, measuring, cutting and attaching the rest of the molding. Now for a final touch, Steve and Barb have elected to faux-finish the beams. After a long day, we can finally relax.

Room's back together.

BARB HIRSCH:

And the ceiling looks absolutely beautiful.

RON HAZELTON:

I love the pecky part.

BARB HIRSCH:

I do too. I can't believe the difference.

STEVE HIRSCH:

I think the beauty to me is, I love the wood but with the focus on the ceiling, it kind of brings the room down a little bit, it makes it a little more cozy.

RON HAZELTON:

Yep.

BARB HIRSCH:

And for name, the speaker — when we got to the speaker, wondering how we were going to get that hole cut. Some really good tips.

RON HAZELTON:

Well, it did take quite a bit of challenging thought on my part.

[LAUGHTER]

Well, the real credit for today's project goes to Barb and Steve who realize that ceilings deserve as much attention as walls and floors when it comes to transforming a room.