How to Repair Broken Floor Tile

Learn how to replace loose or broken ceramic floor tiles

Repair floor tile by first diagnosing what is causing the damage. Here the failure results from a flexing 3/4-inch subfloor that pops the tiles loose--a minimum 1-inch substrate is required to support ceramic floor tile. We remove the debris and set fresh tiles in thinset mortar mixed with an acrylic or latex additive for a stronger bond.

Diagnose the Cause for the Loose or Damaged Tiles

Determine if inadequate subflooring is allowing the tile floor to flex and pop tiles off. A minimum 1-inch substrate should be installed before retiling to make a permanent tile repair, but we patch rather than completely redo the tile floor.

Remove Loose Tiles and Dried Thin-set Debris

Use a large putty knife and hammer to pry up loose tiles without breaking them and scrape the hardened thin-set mortar from the subfloor. Tiles may be reusable if the mortar comes off the back cleanly.

Mix a Batch of Fast Setting Mortar with Latex Additive

Add water per manufacturer's directions to powdered thin-set mix that contains an acrylic or latex additive for a better bond. Mix it with a paddle on a power drill and let it slake for a few minutes.

Trowel the Mortar onto the Tile Floor to Be Patched

Spread the mortar over the tile floor repair area, pressing it firmly in contact with the crevices in the substrate with the smooth side of a trowel. Use the notched side to rake the mortar into uniform furrows and ridges.

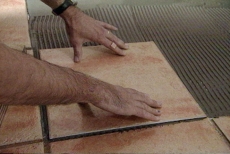

Position and Seat the Whole Tiles in the Mortar

Drop each whole tile into position, pressing and wiggling it gently to seat it in the mortar. Align the tiles and joints with those in the undamaged portion of the tile floor.

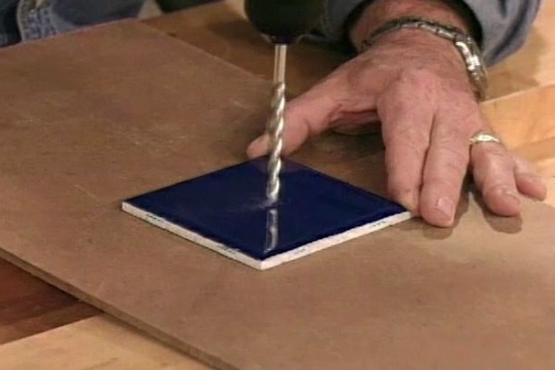

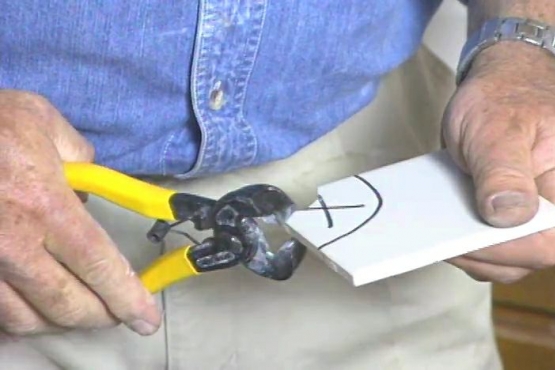

Cut Partial Tiles on a Water-cooled Tile Saw

Measure and then cut tiles on a water-cooled saw to fill in around the edge of the tile floor and cover the face of the steps. The water jet keeps the saw blade cool and ensures precise cuts and smooth edges.

Tap Tiles Gently with a Mallet to Seat Them

Tap each tile gently with a mallet and piece of two-by-four to seat it in the mortar. Tapping against a piece of wood distributes the force of the blow and protects the face of the tile. Dry for two hours.

Apply Tile Grout to Joints Using a Rubber Float

Mix grout and force it into the tile joints with a rubber float. Rake the float across the tiles at an angle to remove excess grout without pulling it out of the joints. Allow the grout to firm.

Clean the Tile Faces with a Sponge and Water

Wring out the sponge in a bucket of water and wipe the excess grout from the face of the tile. Clean the sponge and change the water frequently. After three or four cleanings, let it dry to a haze.

Remove the Grout Haze with a Clean Dry Cloth

Buff the grout haze off the surface of the new tiles with a clean dry cloth. If the existing floor has sealed grout joints, seal the new joints after the floor has cured.

Related Tips

Blog Articles

Maximize Your Yield with DIY Netting for Strawberry Beds

Keep your strawberries safe from pests with our DIY strawberry cage netting solution. Learn how to create sturdy frames and find the best netting for your strawberry plants.

Change It Up: Swapping Out Your Light Switch Plates

Tired of boring light switch covers? Upgrade your home decor with this simple guide on replacing light switch plates and make a statement in every room.

Revamp Your Outdoor Space: How To Stencil A Concrete Patio

Learn how to create a stunning patterned concrete patio with our easy-to-follow instructions for stenciling. Upgrade your outdoor space in no time.