How to Build a Kitchen Breakfast Nook or Banquette

Build an Attractive Breakfast Nook in a Corner of Your Kitchen

Construct a simple corner bench in the kitchen to pair with a table as a breakfast nook and children's craft area. Use two-by-fours for the base frame and MDF board for back and side panels and for the seats. Provide access to storage inside the bench by installing the bench seats with piano hinges that transform the seats into lids.

Read More

Plan the Dimensions of Your Corner Breakfast Nook

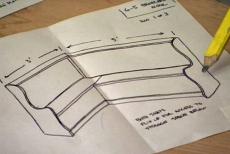

Draw a simple diagram of your corner bench designed to fit neatly into the available wall and floor space and balance its practical size against existing kitchen fixtures.

Determine Proportions for the Height and Depth of the Bench

Measure a comfortable chair. Match your bench proportions to the height of its seat from the floor and the depth of its seat from the back to the front edge where your knees will bend.

Inventory All Required Frame Pieces and Cut to Size

Make a cut list for the wooden components for the bench, noting the number of pieces of a given dimension. Cut the two-by-four components of the frame to size for both seat bases. Cut all the pieces except the panels.

Lay out the Cut Pieces and Begin Assembling the Frame

Arrange the pieces for the frame bottom and apply glue to adjoining surfaces. Insert deeply countersunk screws to attach them securely. Repeat for the other frame components and complete both seat bases.

Cut the Medium Density Fiberboard Panels to Cover the Frames

Support the fiberboard on two-by-fours, using a circular saw to cut the panels to cover the frame. The two-by-fours prevent the cut pieces from moving and pinching or binding the blade. Guide the cuts with a clamping straight-edge.

Join the Two Seat Bases together with Screws

Carry the individual seat frames to the kitchen before joining them. Position the frames for the two bases in an L-shaped configuration and join them securely with long screws.

Secure the Front Panels with Glue and Nail Gun

Apply glue to the front panels and clamp them in place. Secure them with a pneumatic nail gun, driving the nails through the panel into the framework behind.

Attach Back Supports and Wedges to Angle the Backrest

Attach the two back supports, applying glue and clamping the pieces in place before securing them with screws. Nail long wedges on the supports to provide a gentle and more comfortable angle for the backrest panel. Secure the backrest

Draw the Curved Side Panels Using One as a Template

Trace a wooden strip to draw the first curved side panel. Cut with a jigsaw and use that side as a template for the second. Glue and nail the seat backs first, then the side panels and the top trim.

Install the Hinged Seat Lids with Piano Hinges

Attach the hinge to the lid first with countersunk screws and then attach the lid to the base. Use only a few screws until you test the fit. Repeat to install the second lid in the same way.

Related Tips

Blog Articles

Expert Tips: How to Mount a TV on the Wall

Get step-by-step instructions on how to mount a TV on the wall, especially for big screen TVs. Master the art of wall mounting with our tips.

Frustrated by Stripped Screws? Here’s How to Get Them Out Fast

We've all been there. You're in the middle of a project, and suddenly your screwdriver spins uselessly in the screw head. The screw is stripped, and frustration sets in. With a little know-how and this simple trick, you can tackle a stripped screw and get your project back on track.

The Secret to Finishing Plywood Edges

Plywood projects are fantastic, but exposed edges can be an eyesore. This blog post unveils the magic of edge banding - a simple technique to create flawless, finished edges on your plywood projects, making them look professional and ready for paint or stain. Watch the video to learn how to apply edge banding like a pro!