How to Use a Gel Stain to Finish a Cabinet

Remove marks and blemishes before re-finishing to make an old cabinet look like new.

Use some simple wood working tricks to bring an old wood surface back to life. With great products like Minwax Gel Stain on the market, it is easier than you'd think to have old pieces of furniture, looking like new. The old towel cabinet in this project is a great example.

Clean Old Water Damage

In many cases, the black marks that you see on old or antique furniture are a result of the old steel hardware getting wet and oxidizing in the wood. These marks can be cleaned using oxalic acid. Mix the powdered compound with hot water and brush the solution on the drawer fronts until the wood is saturated. No scrubbing is required. Simply set the drawers aside to dry, and as the mixture evaporates, the marks will slowly disappear.

Sanding - The First Pass

Start the sanding process with 120 grit paper. Divide a full sheet into quarters, and then fold the quarter sheet into thirds. This is a perfect size to fit in your hand and will work well for sanding small pieces. Always make sure that you run the sandpaper with the grain of the wood and never across it. After you've sanded the entire piece, wipe it down with a clean, soft cloth to remove the dust.

Repair and Remove Scratches

Compression scratches are caused when the wood is crushed by a direct blow, rather than gouged away. To remove these types of blemishes, soak a cloth in water and then wring it out as much as you can. Place the wet cloth over the compression, and then iron it with a common household clothes iron. The steam that is created from the wet cloth will gradually reconstitute the fibers of the wood that was crushed. Repeat this process until the blemish is gone.

Sanding - The Second Pass

Now that the wood is clean and the surface has been restored, you can make the final sanding pass before applying the finish. Use 220 grit paper for this step, as it will leave a smoother surface for finishing than the 120 would. You can also use a palm or an orbital power sander for this step. For this project, Ron also decided to add some additional trim to the existing cabinet. Apply that trim before the final sanding, so that you can sand off any nail hole filler that you may add during that installation.

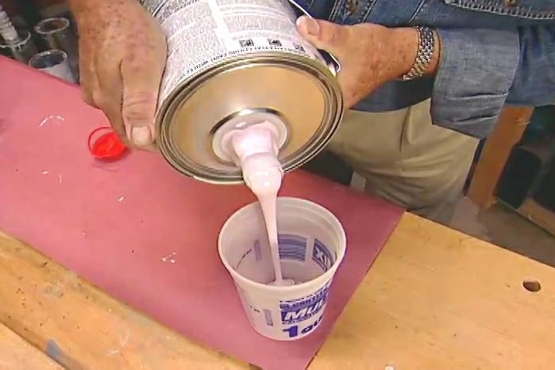

Use a Gel Stain for the Cabinet's Color

For this cabinet, Ron has chosen to use a gel stain made by Minwax. He begins by stirring the product to ensure that the color pigments are distributed evenly throughout. Next, pour the product into a plastic container, as this is easier to dip out of than the can that the product came in. Apply the stain in the direction of the wood grain. The Gel Stain is ideal for vertical surfaces like these because it won't run or drip like traditional stains.

Wipe Away the Excess Gel Stain

After a few minutes, come back with a clean cloth and wipe away the excess stain. You can control color of your final product by varying the pressure on the rag as you wipe. Obviously, the more stain you leave behind, the darker the final product will be.

Finish with an Appropriate Varnish

Since this cabinet is going to be used in the bathroom, Ron has chosen to use a spar urethane varnish that is designed for marine applications. This product will ensure that the cabinet holds up well in the humidity of the bathroom. Apply the varnish using long straight strokes in one direction. You will also want to make sure that the brush you are using is appropriate for the product.

Sand Between Coats

After about 4 hrs, lightly sand the first coat of varnish. This will help eliminate any bumps or rough patches, and will also create a good surface for the 2nd coat to grip on to. Wipe away any excess dust with a tack cloth. Most projects like this require several coats of varnish to create the quality finish that you are looking for.

Related Tips

Blog Articles

Maximize Your Yield with DIY Netting for Strawberry Beds

Keep your strawberries safe from pests with our DIY strawberry cage netting solution. Learn how to create sturdy frames and find the best netting for your strawberry plants.

Change It Up: Swapping Out Your Light Switch Plates

Tired of boring light switch covers? Upgrade your home decor with this simple guide on replacing light switch plates and make a statement in every room.

Revamp Your Outdoor Space: How To Stencil A Concrete Patio

Learn how to create a stunning patterned concrete patio with our easy-to-follow instructions for stenciling. Upgrade your outdoor space in no time.