How to Build a Tree Bench - DIY

Build a Custom Bench around a Tree to Gain Sitting Space and Garden Interest while Protecting the Tree

Design and construct a simple hexagonal redwood bench around your family tree--the geometry of building the hexagonal bench is easier than a circular bench yet provides equal sitting comfort and practicality from all sides because it is symmetrical. Build the bench in sections with leg/supports spaced to avoid the tree's roots and then assemble it around the tree.

Read More

Cut the Six Inner Seat Boards for the Inside Row

Plan the dimensions of the hexagonal custom tree bench to encompass the tree trunk without damaging it or impeding its growth. Set your power miter saw for a 30-degree angle and cut the first row (inner row) of seat boards.

Cut and Miter Remaining Middle, and Outer Seat Boards

Lay two planks parallel to an inner seat board, separated with 1/4-inch spacers. On both ends, extend a 30-degree cutline from the first board across the other two. Cut six sets of inner, middle, and outer planks in this manner.

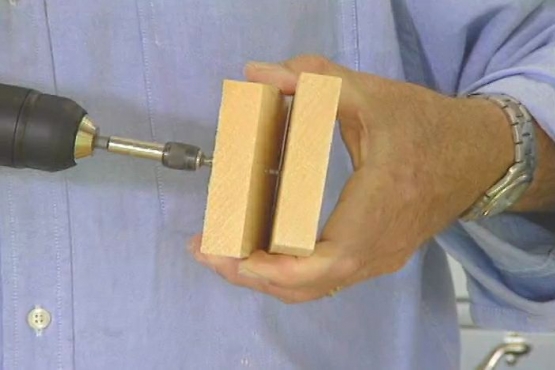

Cut, Assemble, and Secure Six Tree Bench Supports

Build six tree bench supports having two two-by-six legs sandwiched across the top by two one-by-four cross braces. Secure them with galvanized carriage bolts, washers, and nuts. Tighten the nuts with a socket wrench, compressing the wood slightly.

Join Two Pairs of Bench Seat Sections by Attaching Supports

Join two seat sections, drilling pilot holes beneath to screw a support directly over the joint and one at both ends of the assembly. Make two assemblies, reserving the remaining two individual sections for installation once positioned around the tree.

Turn Assembled Sections Upright and Countersink Screws from the Top

Turn the two bench assemblies upright. They are not yet rigid, so drill countersunk pilot holes and screw through the bench top into the support cross braces below. The countersunk screw heads will lie beneath the surface and protect clothing.

Level the Tree Bench, Removing Soil if Necessary

Level the two bench assemblies around the tree, leaving gaps of the exact length for the two remaining seat sections. If necessary, remove soil to level the ground for the tree bench, but avoid the tree roots.

Screw Remaining Bench Seat Boards into Exposed Portion of Supports

Drop remaining tree bench planks into position. Drill countersunk holes to drive screws through the bench top into the support cross braces below. Remember to leave a 1/4-inch space between boards to allow for wood expansion and water drainage.

Apply Sealer to Redwood Tree Bench

Coat redwood with sealer to extend the tree bench life, keep it looking good, and prevent the top from weathering and becoming rough. All these actions will lead to less maintenance labor and make the bench more comfortable as well.

Related Tips

Blog Articles

Expert Tips: How to Mount a TV on the Wall

Get step-by-step instructions on how to mount a TV on the wall, especially for big screen TVs. Master the art of wall mounting with our tips.

Frustrated by Stripped Screws? Here’s How to Get Them Out Fast

We've all been there. You're in the middle of a project, and suddenly your screwdriver spins uselessly in the screw head. The screw is stripped, and frustration sets in. With a little know-how and this simple trick, you can tackle a stripped screw and get your project back on track.

The Secret to Finishing Plywood Edges

Plywood projects are fantastic, but exposed edges can be an eyesore. This blog post unveils the magic of edge banding - a simple technique to create flawless, finished edges on your plywood projects, making them look professional and ready for paint or stain. Watch the video to learn how to apply edge banding like a pro!