How to Build a Table for Craft Projects

Learn how to build a craft table; the table consists of kitchen base cabinets connected with a top covered in durable plastic laminate.

For this next HouseCall, Ron found himself at the crossroads of California, Arizona, and Mexico in the desert city of Yuma, Arizona, and the home of Candace Kirk. Promoting the beauty of Yuma is what Candace does for a living working for the convention and visitor's bureau. In her spare time, she likes to create beautiful things with her arts and crafts projects. Unfortunately, Candace had outgrown her workbench so she called upon Ron to help her build a bigger and better craft table.

Read More

Purchase and Assemble Base Cabinet Kits for Craft Table Supports

Purchase and assemble four base cabinet kits, following manufacturer's instructions. The melamine kits used here have shelves and drawers and are durable and easy to clean--important characteristics in a table for craft projects. Assembly requires less than thirty minutes.

Reinforce the Perimeter of the Table for Craft Projects

Glue wooden supports on the edges of a large piece of Medium Density Fiberboard (MDF) for the craft table. The strips will prevent sagging and provide a surface for attaching trim strips later. Secure glued strips with a nail gun.

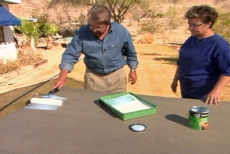

Apply Contact Cement to Craft Table Top Components

Roll contact cement onto the back of a large sheet of plastic laminate. Contact cement bonds to itself, so apply two coats on the porous craft table fiberboard as well. When dry, it goes from white to clear.

Position the Glued Laminate over Boards on the Craft Table

Lay half a dozen temporary boards across the glued surface of the fiberboard table for craft projects. Center the glued back of the laminate across the boards to temporarily prevent the two glued surfaces from making contact until later.

Remove Boards One-by-one and Press together the Glued Craft Table

Slide the boards out one-by-one beginning at one end of the craft table while pressing the exposed laminate and fiberboards surfaces together with a pressure roller. Roll from the center to the edge to force out any air bubbles.

Trim off the Excess Laminate Edges from the Craft Table

Roll the bearing of a laminate cutter along the edge of the fiberboard while the cutter slices through the excess laminate on the table for craft projects. Keep the base flat and move in a slow and even pace.

Secure Hardwood Trim on the Edges of the Craft Table

Miter corner joints on hardwood trim and nail it on the edges of the workbench. The mitered corners make a clean edge, exposing only the face grain rather than coarse end grain that butted corners reveal on the craft table.

Attach Cabinet Backs together to Support the Craft Table

Position pairs of assembled cabinets back-to-back to form two separate craft table bases or supports. Join each pair securely with long wood screws driven from the inside back of one cabinet through the one behind it.

Connect Both Cabinet Bases for the Workbench

Position the two pairs of back-to-back cabinets far enough apart to make a stable base for the craft tabletop. Join them with three lengths of one-by-four stringers and secure them with screws. They will also add support to the top.

Set the Craft Table on the Cabinet Base

Position the finished workbench top on the cabinet base on top of the stringers. Add the drawers that came with the cabinet kits and a variety of bins to hold supplies inside the cabinets.

Related Tips

Blog Articles

Expert Tips: How to Mount a TV on the Wall

Get step-by-step instructions on how to mount a TV on the wall, especially for big screen TVs. Master the art of wall mounting with our tips.

Frustrated by Stripped Screws? Here’s How to Get Them Out Fast

We've all been there. You're in the middle of a project, and suddenly your screwdriver spins uselessly in the screw head. The screw is stripped, and frustration sets in. With a little know-how and this simple trick, you can tackle a stripped screw and get your project back on track.

The Secret to Finishing Plywood Edges

Plywood projects are fantastic, but exposed edges can be an eyesore. This blog post unveils the magic of edge banding - a simple technique to create flawless, finished edges on your plywood projects, making them look professional and ready for paint or stain. Watch the video to learn how to apply edge banding like a pro!